Home

Biography

Tables, Chairs

Cabinet Furniture

Beds, Built-ins, Other Work

Exhibitions, Galleries, News

Articles

Teaching and Student Work

Contact

Richard Jones Furniture

Determining Wood Moisture Content Using a Microwave Oven, © 2024

What follows is an extract from the book Cut & Dried: A Woodworker's Guide to Timber Technology. The

most accurate method of measuring wood moisture content is the

oven-drying method using a conventional oven which, in our case as

woodworkers rather than, say, wood scientists or wood processors means

a domestic oven, e.g., electric convection or fan-assisted types.

Essentially, a sample of wood is cut as described below and cooked in

the oven at ~99 - 101ºC (~210 - 215ºF), weighed at intervals until no

further weight loss is measurable indicating the sample is 'oven dry',

followed by making the calculation shown later. This alternative method

using a common or garden domestic microwave oven gives good results if

the process is undertaken carefully. A good quality set of scales is

also required — within 0.1% accuracy is ideal, although somewhat less

accurate

scales can provide reasonably acceptable results.

The

most accurate method of measuring wood moisture content is the

oven-drying method using a conventional oven which, in our case as

woodworkers rather than, say, wood scientists or wood processors means

a domestic oven, e.g., electric convection or fan-assisted types.

Essentially, a sample of wood is cut as described below and cooked in

the oven at ~99 - 101ºC (~210 - 215ºF), weighed at intervals until no

further weight loss is measurable indicating the sample is 'oven dry',

followed by making the calculation shown later. This alternative method

using a common or garden domestic microwave oven gives good results if

the process is undertaken carefully. A good quality set of scales is

also required — within 0.1% accuracy is ideal, although somewhat less

accurate

scales can provide reasonably acceptable results.You need a sample of wood 25- 32 mm (1” to 1-1/4”) long taken from your sample plank (board). Ideally the sample comes some 400 mm (16”) or more from the end of the plank because wood near the end is unrepresentative of the board as a whole — moisture exchange is more volatile at a board’s end than nearer the centre.

Oven drying in a microwave oven takes between 20 and 45 minutes per sample. 30 minutes is about average. It generally saves a great deal of time over drying wood in a conventional oven. Just as in using a conventional oven for doing the job, this microwave oven drying method requires care and attention to detail. Poor methodology and mistakes in the procedure usually lead to problems and failure.

You need to weigh the wood

samples and I find electronic postal scales purchased at reasonable cost from

an office supplier work well enough for my needs: if you require

more accuracy then better, more expensive scales are required. My

scales provide readings in 1 gramme divisions from zero up to a maximum

of 2200 grammes, and I can select readings in either grammes or ounces.

You need to weigh the wood

samples and I find electronic postal scales purchased at reasonable cost from

an office supplier work well enough for my needs: if you require

more accuracy then better, more expensive scales are required. My

scales provide readings in 1 gramme divisions from zero up to a maximum

of 2200 grammes, and I can select readings in either grammes or ounces.To dry the wood I use a turntable type microwave oven that has several power settings. The only two settings I use are the very lowest setting and the next higher setting which is Defrost – your oven may have a different configuration, but whatever marked settings are available restrict yourself to the lowest one or two power levels. As the wood is heated moisture evaporates from all exposed surfaces, including the bottom face resting on the turntable; three to five paper kitchen towels laid under the wood absorb and dissipate the condensed moisture drawn downwards from the wood. If you’re testing several samples make sure they don’t touch each other because this can concentrate the energy and lead to smoking and possibly fire.

If the wood starts to smoke at any time during the drying procedure the sample is ruined and you need to start again with a new sample. Smoking during the cooking means you have burnt away some of the wood volume and weight measurements taken thereafter are inaccurate, and is likely the result of too aggressive heating for too long. This is why I mostly restrict myself to the lowest power setting and short bursts of heat. I seldom use the second lowest power setting, Defrost on my microwave oven, but I do sometimes use it for the initial drying cycle of very wet wood.

As described above, the ideal wood sample is a full thickness and width piece taken at least 400 mm in from the end of your board that is 25- 32 mm (1” to 1-1/4”) long. Weigh your sample and make a note of this. If the sample is already partially dried, e.g., air dried to somewhere between 25% MC to 15% MC, cook the wood at the lowest oven setting for between one and one and a half minutes in the first cycle. If you know the wood is already quite dry I recommend you cook it at the lowest setting of the oven for no more than 45 or 60 seconds to start with.

Where wood is definitely at fibre saturation point (FSP, 30% MC) or above it’s my experience that the first cooking should last no more than between one and a half minutes and two and a half minutes with the oven at the second lowest setting. Even in this circumstance I prefer to use the lowest oven setting for perhaps only one and a half minutes: it takes a few minutes longer to dry the wood but I prefer that to starting again because I’ve burnt the sample.

After the first cycle weigh the sample or samples again to form an impression of how quickly the wood loses weight, i.e., loses water. Let the sample rest for a minute or so and re-cook it for between 45 and sixty seconds and re-weigh.

Continue with this routine until you can’t measure any weight change, i.e., less than 0.1 of a gramme variation if you are using highly accurate scales. My scales read only to the nearest gramme so I stop cooking when I get four to six low weight readings the same.

With this point reached use the following formula to calculate the moisture content of the wood prior to drying it:

MC% = ((WW – ODW)/ ODW) X 100, where WW is the Wet Weight of the sample, and ODW represents the wood sample’s Oven Dry Weight.

The following cautions are important.

Do not use high microwave oven power settings. The internal heat built up in the wood needs to dissipate and high settings cause rapid heat build up, smoke and even fire.

The more wood tested in one go, the more time is required to complete the job. This is useful because after the initial heating of a large batch you can rotate from one sample to the next in the oven with short bursts of cooking for each piece. This gives each sample a longer break between heating cycles thus reducing the chance of overheating any one piece.

It’s my experience that kiln dried wood samples react differently to cooking than green or air dried samples. It’s better to avoid mixing samples of very different moisture contents and different wood species during the test, but it's possible if you proceed with care.

Being sure that the wood sample or samples is, or are, truly oven dry requires patience and careful weighing using accurate scales. It’s better, and safer, to use several short cycles in the oven at low settings than it is to try and rush the job using a higher setting for extended times. The latter strategy usually results in burning the wood and failure.

These final closing warnings probably seem obvious, but they’re worth mentioning. Removing cooked wood from the oven requires care. It’s usually hot and can and does burn skin. You probably don’t need to ask how I know that - use an oven glove or heavy leather work gloves. Also be aware that at the end of testing, and unknown to you, wood might have charred on the inside: it can smoulder and burn, and could set fire to rubbish in bins, etc. Careful disposal is essential. The safest thing is to put the cooked wood in water when you’ve finished to ensure it doesn’t burst into flames later — it can happen.

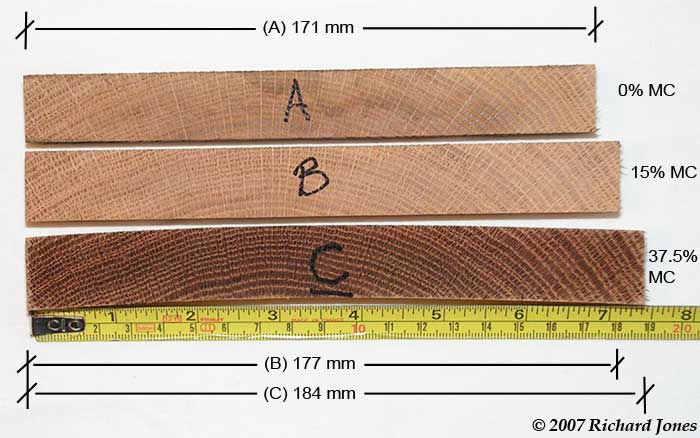

Description and explanatory notes for the photograph above.

Three 25 mm (1”) long lengths cut sequentially from an English oak board were prepared and tested. Each piece started the test weighing 73± grammes, and approximately 177 mm wide by 21.5 mm thick.

Piece A was kept near a radiator for three days prior to further experiments. The weight recorded after this additional drying was 69 grammes. Subsequent microwave oven drying to 0%MC and a final weight of 65 grammes shows the piece started the test at 6.5% MC. After oven drying it measured 171 mm wide X 21 mm thick.

B, the middle section of the three cut pieces, was placed outside but sheltered from rain for three days after which it too was oven dried to 0% MC. Prior to drying it weighed 76 grammes with a dry weight of 66 grammes. This equates to just over 15% MC indicating its MC rose probably 6 - 7 percentage points over the three days. Dimensions of the piece just before oven drying were 177 mm wide by 21.5 mm thick.

C was weighed and measured after three days of soaking in water. It’s weight after soaking was 92 grammes and measured 184 mm wide by 22 mm thick. Subsequent oven drying to 0% MC and a final weight of 67 grammes show the MC of this piece was 37.5% after soaking.

Dividing the narrowest width (A) by the widest width (C), i.e., 171 / 184 = 0.93 or ~7% shrinkage from fibre saturation point (FSP) or green, or 30% MC. Similarly dividing the narrowest thickness by the greatest thickness, i.e., 21 / 22 = 0.955 or 4.5% shrinkage.

The photograph was taken after A was oven dried but before pieces B and C were dried. The dimensions are very approximate as I used only a steel rule to measure. Although measurements are only approximate it’s interesting to note that the tangential shrinkage (~7%) and radial shrinkage (~4.5%) for this piece of oak are reasonably close to European oak shrinkage percentage figures provided in many wood movement tables, i.e., 8.9% tangentially, and 5.3% radially from green (FSP) to oven dry (0%).

Explanatory note on the formula provided above

Every now and then I am questioned about the arrangement of the formula for calculating the percentage of water in a piece of wood, so it is important to understand what it calculates: it uses the weight of completely dry wood as the base weight and figures how much extra weight is caused by the water in it. Knowing this allows us to calculate what percentage this water forms over the dry wood base weight. Using some easy to visualise and calculate numbers illustrates the principle, e.g., numbers such as:

• Wet Weight = 20 grammes

• Dry weight = 15 grammes

I recall a learner coming to me with these numbers as examples, and she had questions. Using the formula given earlier the calculation is ((20-15)/ 15) X 100 = 33.3% MC. This learner, in trying to understand the basis of the calculation, turned the formula around to calculate thus: ((WW – ODW)/ WW) X 100 giving the sum ((20- 15)/ 20) X 100 = 25%. We discussed the different results, i.e., 33.3% and 25%, and it is easy to see that a 5 gramme weight loss is a quarter of 20 grammes, i.e., 25%. Similarly it is easy to see that a 5 gramme weight gain is one third of 15 grammes. As soon as the learner understood that the base line for the sum is the dry weight of the wood, not the wet weight, all was clear to her. She was then able to visualise how wood MC figures such as 100% made sense, e.g., wet weight, 100 grammes and oven dry weight of 50 grammes.

Home Biography Tables, Chairs Cabinet Furniture Beds, Built-ins, Other Work Exhibitions, Galleries, News Articles Teaching and Student Work

Contact

Contact

© 2024 Richard Jones